Eco-Materials

Use of bio-based plastics

CASIO uses bio-based plastics derived from renewable raw materials in selected watch models. These materials can help reduce environmental impact and promote the transition to a circular economy. They are also believed to have the potential to reduce CO₂ emissions and decrease dependence on fossil resources.

Design meets sustainable materials

Here you will find selected watch models that already use bio-based plastics.

Bio-based plastics

Bio-based plastics are polymers produced by chemical or biological synthesis from plant-based or other renewable organic materials.

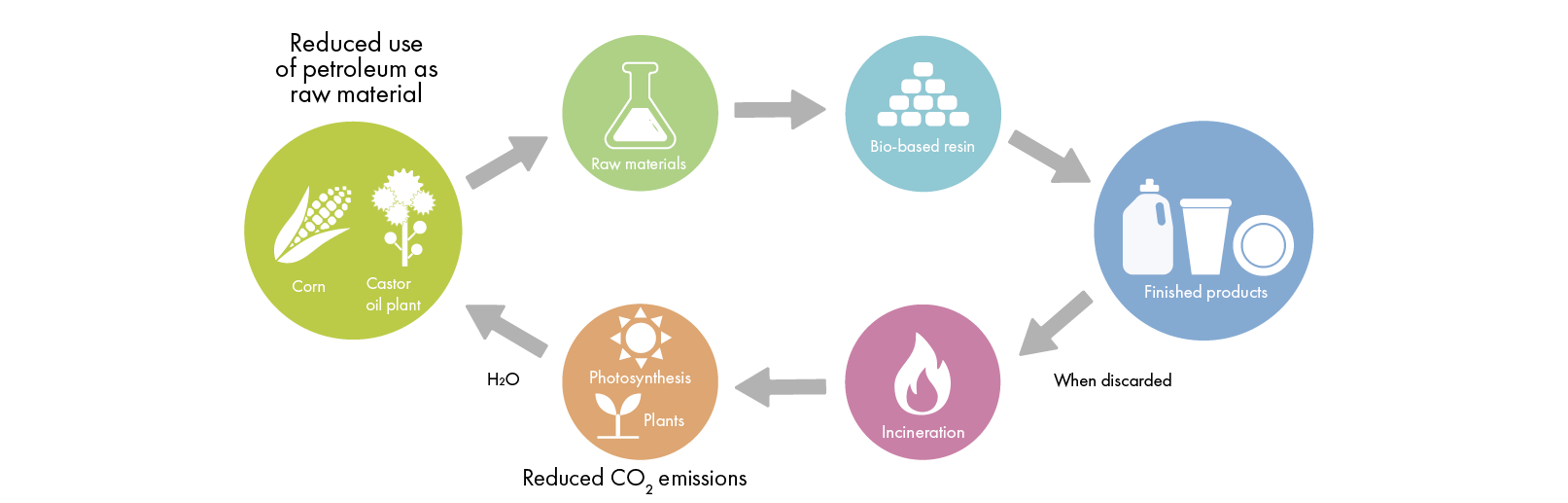

From raw material to biomaterial

Renewable organic raw materials such as castor oil and corn are used to produce bio-based plastics. These plant-based raw materials are used to create biomaterials that are specifically processed for use in watches. In the form of pellets, they are used in the casting process for watch components in selected CASIO models.

From biomaterial to PRO TREK

The biomaterials derived from castor beans and corn are used by CASIO in selected PRO TREK models, among other things. There, they are processed into components such as the case, wristband and case back, blending seamlessly into the design and functional characteristics of the model series.

Ecological Cycle of Bio-Based Resin

Biomass, which is used as raw material, binds carbon (CO2) from the atmosphere as it grows. This means that, as long as the biomass is reproduced, there is no net increase in atmospheric CO2 when biomass is incinerated. Accordingly, the use of biomass plastics produced with biomass materials is widely thought to help curb emissions of CO2. Also, since they are produced from renewable organic resources, they are able to help reduce the use of exhaustible resources, including fossil resources.